< Previous | Contents | Next >

Section 8-1 Diesel Engines 1

801. Application

1. The requirements in this Section apply to tests and inspection for the approval of new type diesel engines or no service records to the Society on the basis of the requirements in Pt 5, Ch 2, 211. 3 of the Rules.

2. Notwithstanding the preceding 1, a part or whole of the tests and inspection specified in this Section may be omitted when deemed appropriate by the Society in consideration of the service ex- perience of similar type engines, etc.

3. An approval for a particular type of engine of which tests and inspection carried out at any place at any manufacture will be accepted for all engines of the same type including different number of cylinders built by licensees and licensors.

4. The requirements in this Section apply, in general, to each engine type of which either of the fol- lowing is different to that of an approved engine type.

(1) Bore

(2) Stroke

(3) Method of injection(direct or indirect injection)

(4) Kind of fuel (liquid, dual-fuel, gaseous)

(5) Working cycle(2-stroke, 4-stroke)

(6) Gas exchange

(7) Maximum continuous power per cylinder at maximum continuous revolution or brake mean ef- fective pressure at maximum continuous power. (If an approved engine which has proven reli- ability in service is increased or decreased in output by not more than 10 %, a new approval is not necessary.)

(8) Method of pressure charging (pulsating system, constant pressure system)

(9) Charging air cooling system (with or without intercooler, number of stages)

(10) Cylinder arrangement (in-line, vee-type)

5. Where the manufacturer apply to the approval by manufacturer's rating not the maximum continuous output of engine, the Society correspondingly apply to the requirements in this Section.

6. If an electronically controlled diesel engine has been type tested as a conventional engine the Society may waive the integration test in stage B provided the results of the individual tests would be similar.

802. Data to be submitted

In addition to those specified in 102., the documents is to be submitted according to Table 5.1.4

of Pt 5, Ch 1, 203. of the Rules and Pt 5, Ch 1, 203. of the Guidance relating to the Rules.

803. Type tests

1. Test stages

The type tests are subdivided into three stages below.

(1) Stage A (Internal tests)

Functional tests and collection of operating values including test hours during the internal tests, the relevant results (including photographs which show the conditions of each component after the internal tests) of which are to be presented to the Society during the stage B.

(2) Stage B (Approval tests)

Operation test in the presence of the Surveyor.

(3) Stage C (Component inspection)

Component inspections by the Surveyor after completion of the test programme. The engine manufacturer will have to compile all results and measurements for the engine tested during the approval tests in a report, which will have to be submitted to the Society.

Guidance for Approval of Manufacturing Process and Type Approval, Etc. 2015 81

![]()

2. Details of tests

Test items on stage A, B and C are to be as given in Table 3.8.1. However, during the stage B, deviations from the items, if any, are to be agreed with the Society.

Table 3.8.1 Details of test in stage A, B and C

Test stage | Details of test |

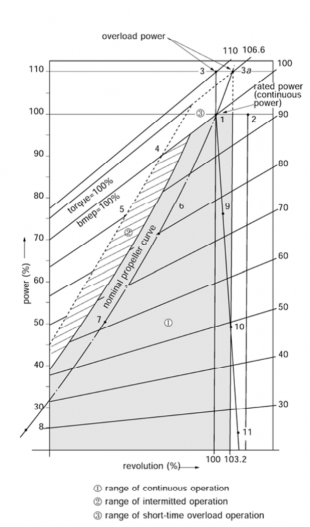

stage A | (1) Operation at the load points 25 %, 50 %, 75 %, 100 % and 110 % of the maximum rated power and other load points considered important, at engine speed of: (a) along the nominal (theoretical) propeller curve and at constant speed for propulsion engines (b) at constant speed for engines intended for generating sets or auxiliary machinery (2) Operation at the limit points of the permissible operating range (3) For turbocharged engines the achievable continuous output is to be determined in the case of turbo- charger damage as follows: (a) engines with one turbocharger, when rotor is blocked or removed (b) engines with two or more turbochargers, when damaged turbocharger is shut off. (4) If an engine can be satisfactorily operated at all load points without using mechanically driven cyl- inder lubricator is to be verified. (5) For engines which may operate on heavy fuel oil suitability will be proved in an appropriate form. (6) Other items deemed to be verified by the Society. (Vibration measurement, torsional vibration meas- urement, noise measurement, etc.) |

stage B | (1) Operation at each load point below (an operating time of two hours is to be required at the load point in (a) and two sets of readings are to be taken at a minimum interval of one hour, an operat- ing time of 0.5 hour can be normally assumed per each load point other than (a)) (a) Rated power, i.e. 100 % output at 100% torque and 100% revolution (corresponding to load point 1 in Fig 3.8.1) (b) 100% power at maximum permissible revolution (corresponding to load point 2 in Fig 3.8.1) (c) Maximum permissible torque (normally 100 %) at 100 % revolution (corresponding to load point 3 in Fig 3.8.1) or maximum permissible power (normally 110 %) and revolution according to nominal propeller curve (corresponding to load point 3a in Fig 3.8.1) (d) Minimum permissible revolution at 100 % torque (corresponding to load point 4 in Fig 3.8.1) (e) Minimum permissible revolution at 90 % torque (corresponding to load point 5 in Fig 3.8.1) (f) Partial loads, e.g. 25 %, 50 %, and 75 % of rated power and revolution according to nominal propeller curve (corresponding to load points 6, 7 and 8 in Fig 3.8.1) for propulsion engines (g) Partial loads, e.g. 25%, 50% and 75% of rated power and rated speed with constant governor setting (corresponding to load points 9, 10 and 11 in Fig 3.8.1) for engines intended for gen- erator sets or auxiliary machinery (2) Maximum achievable power when operating along the nominal propeller curve in the case specified in (3) of stage A for propulsion engine (3) Maximum achievable power when operating with constant governor setting for rated revolution in the case specified in (3) of stage A for engines intended for generator sets or auxiliary machinery (4) Lowest engine revolution according to nominal propeller curve for propulsion engines (5) Starting tests, for non-reversible engines and/or starting and reversing tests, for reversible engines (6) Governor test. However, prime movers for generators are to comply with the requirements in Pt 6, Ch 1, 202. of Rules for the Classification of Steel Ships (7) Testing the safety system, particularly for overspeed and low lubricating oil pressure (8) For electronically controlled diesel engines integration tests shall verify that the response of the com- plete mechanical, hydraulic and electronic system is as predicted for all intended operational modes. The scope of these tests shall be agreed with the Society for selected cases based on the FMEA. (9) Supplementary tests when required for engines intended for emergency services (10)Other test items deemed necessary by the Society |

82 Guidance for Approval of Manufacturing Process and Type Approval, Etc. 2015

![]()

![]()

Table 3.8.1 Details of test in stage A, B and C (continued)

Test stage | Details of test |

stage C | During the stage C, immediately after the test run the components of one cylinder for in-line engines and two cylinders for V-engines are presented for inspections. The following components are concerned: (1) Piston removed and dismantled (2) Crosshead bearing, dismantled (3) Crank bearing and main bearing, dismantled (4) Cylinder liner in the installed condition (5) Cylinder head, valves disassembled (6) Control gear, camshaft and crankcase with opened covers (7) Further components deemed necessary by the Society |

Fig 3.8.1 Power/Revolution Diagram

Guidance for Approval of Manufacturing Process and Type Approval, Etc. 2015 83

![]()

![]()